The Harley Davidson 103 compensator serves a critical purpose in your motorcycle’s engine, smoothing out the torque that the engine generates and ensuring a more pleasant riding experience. You love the power and reliability your Harley’s 103 engine offers, but it’s important to recognize that even the sturdiest components have their weak spots.

It’s not uncommon to encounter issues with your bike’s compensator, such as strange noises, difficulty shifting gears or even clutch slippage. Being aware of these potential problems can help you address them before they lead to more severe mechanical troubles. After all, staying on top of maintenance ensures that you can continue to enjoy the open road with the signature rumble of your Harley beneath you. But surely there’s more that you need to know, right?

Related read:

– Is the Harley 103 a Good Engine? Yes, No, Maybe So

– The Best Tuner for Harley 103 Engines Is FINALLY Here!

Fed up with your 103’s ongoing compensator issues? I recommend checking out the Darkhorse Man O’ War Compensator to nip these problems in the bud, and get some nice performance gains in the process!

Understanding the Harley Davidson 103 Compensator

When you rev up your Harley Davidson, the compensator is hard at work ensuring smooth power delivery from the engine to the drive train. Let’s get a closer look at what makes up this component and its critical role in your ride’s performance.

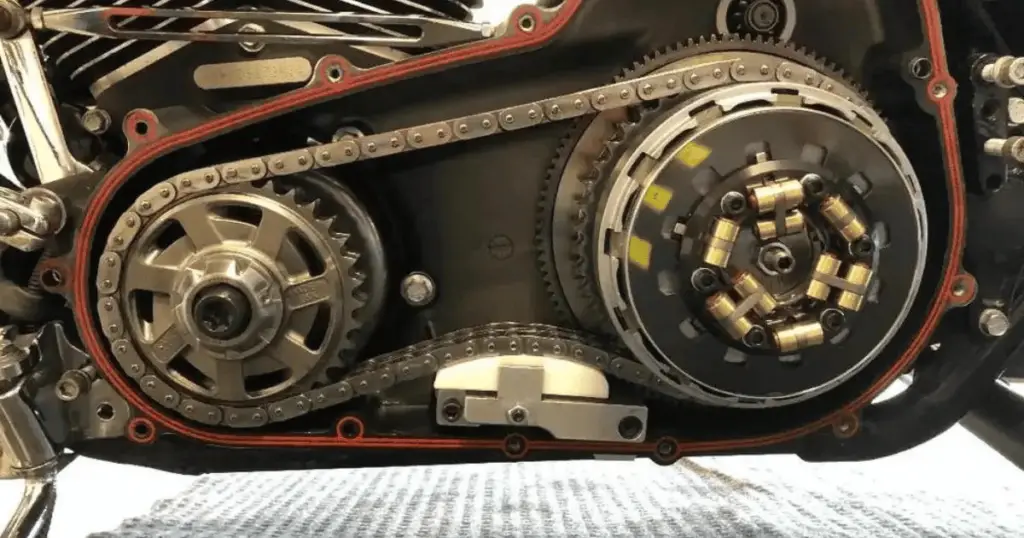

Components of the Compensator

The compensator, often located at the front of the sprocket shaft on your Harley Davidson 103 engine, includes several key components:

- Spring Pack: Absorbs engine torque fluctuations.

- Sliding Cam: Transfers torque from the engine to the sprocket.

- Retaining Bolt: Holds the compensator assembly firmly onto the sprocket shaft.

Together, these parts work in harmony to buffer the transfer of power from the engine to the motorcycle’s drive system.

Role in Power Delivery

Your Harley’s compensator is essential for moderating the shock to the drivetrain during power delivery. It works by:

- Evening Out Torque: It smoothes out the pulses of power as they travel from the engine to the rear wheel, protecting components from stress and wear.

- Maintaining Performance: A well-functioning compensator ensures that your Harley delivers consistent performance without disruptive noise or vibrations.

Read next: Finding The Best Harley Compensator Upgrades Available Today

Common Harley Davidson 103 Compensator Problems and Symptoms

Your Harley Davidson 103 may show clear signs of compensator problems which need to be recognized quickly to maintain the bike’s performance. Here are the specific issues and symptoms you might encounter.

Excessive Vibration and Rattling

Excessive vibration and a rattling noise from the engine area during operation can indicate a failing compensator. These symptoms are more than just an annoyance; they’re a sign that your motorcycle is asking for help.

Difficulty Shifting Gears

You might experience difficulty shifting gears, especially when engaging the first gear or finding neutral. This is often accompanied by a rough transition between gears, a sign that the compensator isn’t performing as it should.

Startup and Idling Problems

If your bike’s compensator is failing, you could face stuttering or stalling upon startup. A hot engine can exacerbate these issues, leading to grinding sounds or a complete stall during idling. It’s crucial to address these starting issues to prevent potential damage.

Inspecting the Compensator Assembly

The compensator plays a crucial role in your Harley’s performance. Regular inspection helps identify early signs of wear that can prevent noisy and potentially damaging issues.

Signs of a Worn Out Compensator

When your compensator begins to wear out, you may experience difficulty shifting gears, particularly when engaging first gear or finding neutral. It’s essential to catch these early signs to avoid further damage to your engine’s internal components.

- Early Signs to Look Out For:

- Difficulty with gear shifts

- Unusual noise during startup or gear engagement

Noise Diagnosis

If you start hearing a clunking or rattling sound from the engine area, especially when your bike is idling or in neutral, it could indicate a problem with the internal sprocket noise linked to a failing compensator. These sounds shouldn’t be ignored as they signify that your compensator assembly requires immediate attention.

- Common Noises and Their Potential Causes:

- Clunking: Could be a sign of internal sprocket issues.

- Rattling: Sometimes linked to a loose or malfunctioning compensator camshaft.

Visual Inspection Tips

A hands-on visual inspection can reveal a lot about the health of your compensator assembly. Look for any metal shavings or debris around the compensator area, as these could indicate internal wear. Checking the primary chain tension shoe during your visual inspection is also advisable to ensure it’s in good condition.

What to Look For:

- Metal shavings or debris

- Condition of the primary chain tension shoe

Visual Inspection Steps:

- Ensure your bike is safely supported and cool.

- Remove the necessary covers to gain access to the compensator.

- Look for physical signs of wear or damage such as scoring or pitting on the compensator’s surfaces.

- Inspect the primary chain tension shoe for wear.

Be proactive in inspecting your compensator assembly to maintain the smooth operation and longevity of your Harley Davidson 103.

Troubleshooting Advanced Compensator Issues

In this section, we’ll address complex problems associated with your Harley Davidson 103 compensator. By identifying and addressing these advanced issues, you can ensure a smoother and more reliable ride.

Diagnosing Transmission and Drivetrain Problems

To diagnose transmission and drivetrain issues stemming from the compensator, start by listening for a clunking sound during startup or a rattling noise when idling. These sounds can indicate internal wear. Have a methodical approach; begin by checking the compensator torque values and inspect for any visible damage. Don’t overlook the importance of clean and adequate lubrication, which can greatly influence compensator performance.

Handling Frequent Kickbacks

Frequent kickbacks during starting are not just annoying—they’re a symptom of a deeper issue, oftentimes related to the compensator. Ensure that your engine is properly tuned and timed. If kickbacks persist, it might be necessary to investigate the compensator sprocket for correct alignment and wear. Adjustments or replacements may be in order if these parts show significant usage.

Addressing Metal Particles and Shavings

Finding metal particles or shavings in your oil can be alarming. These can originate from a failing compensator and indicate severe internal wear. Regularly check your oil for such contaminants. If found, a closer inspection of the compensator assembly is warranted. Replacing worn components early can prevent more extensive damage to your motorcycle’s engine and drivetrain.

Maintenance and Preventative Care Practices

Proper maintenance can ward off many of the common compensator issues you might face with your Harley Davidson 103. By sticking to a schedule and knowing what to look for, you’ll keep your ride smooth and avoid unnecessary repairs.

Regular Maintenance Recommendations

Your Harley Davidson 103 compensator will benefit from regular maintenance checks as outlined in your service manual. To keep things simple, here’s a checklist:

- Inspect every 5,000 miles: Check the compensator for any signs of wear and tear.

- Follow the service schedule: Your service manual includes specific intervals for thorough inspections and service tasks.

Lubrication and Cleaning

A well-lubricated compensator is key to preventing noise and wear. Here’s how you can ensure proper lubrication and cleanliness:

- Oil Check and Change: Regularly check your engine oil level and look for any metal shavings which might indicate compensator wear. Change the oil and filter as recommended in your service manual.

- Clean Regularly: Dirt and grime can accelerate wear. Cleaning the area around the compensator helps you spot issues before they worsen.

Repair or Replace: Making the Right Choice

Deciding between repairing or replacing your Harley Davidson 103 compensator is critical for maintaining your motorcycle’s performance. Consider the costs involved, advantages of aftermarket options, and the right time for each action.

When to Fix vs. When to Replace

Fixing your compensator can be a viable choice if the issue is minor, such as small worn parts that don’t necessarily compromise the overall component integrity. However, replacing becomes essential when you frequently experience symptoms like excessive noise, trouble shifting gears, or when the compensator fails completely.

- Fix: Minor wear or damage

- Replace: Persistent noise, shifting issues, or complete failure

Cost Considerations

When facing compensator issues, you must weigh the cost of a quick fix against a full replacement. A repair may save you money upfront but could lead to more expenses if problems persist. Here’s a basic cost comparison:

- Repair Costs: Potentially lower, but may recur if the issue isn’t fully resolved

- Replacement Costs: Higher initially but could be more cost-effective in the long run

Aftermarket Options and Upgrades To Consider

Choosing aftermarket options and upgrades not only can fix existing issues but also enhance performance and longevity. When considering an upgrade, look out for reputable brands that specialize in Harley compensators. An upgrade often offers better materials and design improvements over stock parts.

- Aftermarket Benefits:

- Improved durability

- Enhanced performance

- Potentially saves money over time by reducing the need for future repairs

Remember to assess your motorcycle’s current condition and usage patterns when making your choice. Your decision should prioritize both immediate needs and long-term benefits to ensure a smooth ride.

Frequently Asked Questions

In this section, you’ll find common inquiries about the Harley Davidson 103 compensator, offering insight into symptoms, frequency, diagnosis, performance impact, replacement, and possible upgrades.

What are common symptoms indicating a compensator issue on a Harley Davidson 103?

Your Harley’s compensator is crucial for smooth operation. Watch out for loud clunking noises during startup, shifting difficulties, and unusual sounds during idle, which might indicate a compensator problem.

How often do Harley Davidson 103 compensator problems occur?

Compensator issues are not uncommon and can emerge with wear and tear. Regular servicing is necessary to spot early signs and avoid frequent problems.

What are the steps for diagnosing noise from a Harley 103 compensator?

To diagnose a noise, first check for loose parts or damage. Then verify the primary chain tension and listen for sound variations during operation to pinpoint compensator issues.

Can a compensator failure affect the performance of my Harley Davidson 103?

Yes, a failing compensator can lead to rough transitions between gears, affecting your ride’s performance. Immediate attention can prevent further complications.

Is it advisable to upgrade the compensator on my Harley Davidson 103, and what are the benefits?

Upgrading your compensator can reduce noise and improve durability. Benefits include smoother gear transitions and potentially longer compensator life.

Leave a Reply

You must be logged in to post a comment.