If you own a Harley Davidson motorcycle with a hydraulic clutch, you may have experienced some issues with it. Hydraulic clutch problems are not uncommon in Harleys, and they can be frustrating to deal with. Fortunately, there are some steps you can take to prevent and fix these problems.

One of the most common hydraulic clutch problems in Harley Davidson motorcycles is clutch slippage. This occurs when the clutch fails to engage properly, causing the engine to rev without transferring power to the wheels. Other issues may include leaks or damage to the seals and hoses. Regularly checking fluid levels and inspecting the seals and hoses can help prevent these problems from occurring.

If you do experience hydraulic clutch problems with your Harley, there are some fixes you can try. For example, bleeding the clutch can help remove any air bubbles that may be causing issues. Otherwise, replacing damaged seals and hoses can help restore proper clutch function. With proper maintenance and care, you can keep your Harley’s hydraulic clutch running smoothly. But it’s not that simple is it? You’re right, so keep reading and let’s break it down!

Related read: Harley Davidson Clutch Replacement Cost: My Total Overview

Understanding Harley Hydraulic Clutch Systems

If you own a Harley Davidson motorcycle, you know that the clutch system is an essential component of the bike. Understanding how the hydraulic clutch system works is important for maintaining your bike and preventing any problems down the road. In this section, we’ll go over the components of the hydraulic clutch system and compare it to the cable clutch system.

Components of the Hydraulic Clutch

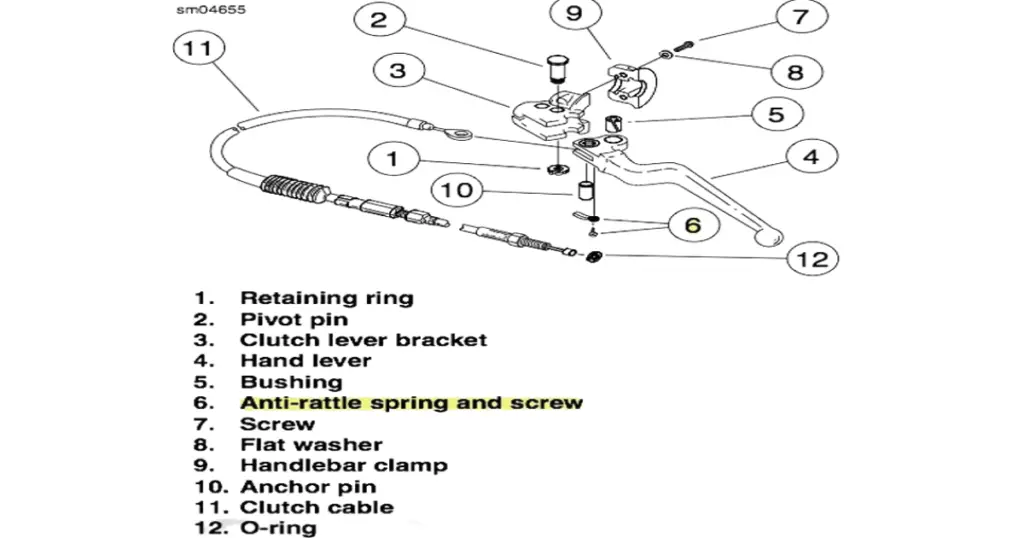

The hydraulic clutch system consists of several components that work together to engage and disengage the clutch. These components include:

- Clutch lever: The clutch lever is located on the left side of the handlebar and is used to engage and disengage the clutch.

- Clutch master cylinder: The clutch master cylinder is located near the clutch lever and is responsible for generating hydraulic pressure that engages the clutch.

- Slave cylinder: The slave cylinder is located near the clutch housing and is responsible for transmitting hydraulic pressure to the clutch.

- Hydraulic lines: These lines carry the hydraulic fluid from the master cylinder to the slave cylinder.

- Hydraulic fluid: The hydraulic fluid is used to generate the hydraulic pressure needed to engage the clutch.

Hydraulic Clutch vs Cable Clutch

Harley Davidson motorcycles used to come with cable clutch systems, but many models now come with hydraulic clutch systems. So what’s the difference?

The main difference between the two systems is how they engage the clutch. Cable clutch systems use a cable to physically pull the clutch plates apart, while hydraulic clutch systems use hydraulic pressure to engage the clutch. This means that hydraulic clutch systems require less effort to engage the clutch, making them easier to use for long periods of time.

Another advantage of hydraulic clutch systems is that they are self-adjusting. Cable clutch systems require periodic adjustments to ensure that the clutch is engaging properly, while hydraulic clutch systems automatically adjust themselves as needed.

Overall, the hydraulic clutch system is a reliable and efficient way to engage and disengage the clutch on your Harley Davidson motorcycle. By understanding how it works and keeping up with proper maintenance, you can ensure that your bike runs smoothly and avoid any potential problems in the future.

Common Harley Hydraulic Clutch Problems

If you own a Harley, you may experience some common hydraulic clutch problems. These issues can be frustrating, but with proper maintenance and troubleshooting, you can fix them. Here are some of the most common hydraulic clutch problems in Harleys and how to fix them.

Clutch Slippage

One of the most common hydraulic problems with any model of Harley is clutch slippage. In the case of clutch slippage, the clutch fails to engage properly. As a result, the engine revs to the next gear but it fails to transfer the power to the wheels. Consequently, the bike experiences higher rev without the drive.

To fix this issue, you need to check the clutch cable adjustment. Ensure that the clutch cable is not too tight or too loose. If the clutch cable is too tight, it will cause the clutch to slip. On the other hand, if the clutch cable is too loose, the clutch will not engage at all.

Difficulty Shifting Gears

Another common hydraulic clutch problem in Harleys is difficulty shifting gears. If you are having trouble shifting gears, it could be due to a low fluid level or contaminated fluid. You should check the fluid level and top it up if necessary. Also, inspect the fluid for any contamination or debris. If the fluid is contaminated, you need to flush the system and replace the fluid.

Clutch Lever Issues

If you are experiencing issues with the clutch lever, it could be due to a worn-out clutch lever or a damaged slave cylinder. You should inspect the clutch lever and slave cylinder for any damage or wear. If the clutch lever is worn out, you need to replace it. Similarly, if the slave cylinder is damaged, you need to replace it.

Fluid Leaks and Contamination

Fluid leaks and contamination are common hydraulic clutch problems in Harleys. You should regularly inspect the seals and hoses for leaks or damage. If you notice any leaks or damage, you need to replace the seals or hoses immediately. Also, check the fluid for any contamination or debris. If the fluid is contaminated, you need to flush the system and replace the fluid.

In conclusion, if you are experiencing any of these hydraulic clutch problems in your Harley, you should take immediate action to fix them. With proper maintenance and troubleshooting, you can keep your Harley running smoothly.

Related read: Harley Davidson Fuel Pump Problems: Tips, Tricks & More

Harley-Davidson Clutch Recalls and Solutions

If you own a Harley-Davidson motorcycle, you may have experienced issues with your hydraulic clutch. While proper maintenance can prevent many problems, there have been instances where Harley-Davidson has had to issue recalls to address clutch issues. In this section, we will discuss how to recognize symptoms of a recall and how to address any recall issues.

Recognizing Recall Symptoms

If you experience any of the following symptoms, your Harley-Davidson motorcycle may be affected by a clutch recall:

- Difficulty disengaging the clutch

- Clutch slipping or not engaging properly

- Reduced hydraulic pressure in the clutch system

- Clutch adjustment not working properly

If you are experiencing any of these symptoms, it is important to check if your motorcycle is affected by a recall. You can check the Harley-Davidson website or contact your local dealership for more information.

Addressing Recall Issues

If your Harley-Davidson motorcycle is affected by a recall, it is important to address the issue as soon as possible. Ignoring the issue could lead to further damage and potential safety hazards.

Harley-Davidson has issued several recalls related to clutch issues, including a recall in 2021 for certain 2020 and 2021 Touring, CVO Touring, and Trike motorcycles due to a clutch assembly issue that could cause the clutch to not disengage. If your motorcycle is affected by a recall, contact your local dealership to schedule a service appointment.

It is also important to note that proper maintenance can prevent many clutch issues. Regularly checking fluid levels and inspecting seals and hoses for leaks or damage can help prevent problems before they occur. Additionally, ensuring proper clutch adjustment can help prevent premature wear and tear on the clutch system.

If you experience any symptoms related to a clutch issue, it is important to check if your Harley-Davidson motorcycle is affected by a recall. Addressing the issue as soon as possible can prevent further damage and potential safety hazards. Proper maintenance can also help prevent many clutch issues from occurring.

Related read: Round ‘Em Up: What Year Harleys To Avoid? (Full Overview)

Troubleshooting and Repair Steps You Can Take

If you are experiencing problems with your Harley’s hydraulic clutch, don’t worry. With proper troubleshooting and repair, you can get your bike back on the road in no time. Here are some tips to help you identify the problem and repair it.

Identifying the Problem

The first step in troubleshooting your Harley’s hydraulic clutch is to identify the problem. Here are some possible causes of clutch problems:

- Low hydraulic fluid levels

- Leaks or damage to the seals or hoses

- Worn or damaged clutch plates

- Premature wear of the clutch components

If you notice any of these symptoms, it’s time to investigate the problem.

DIY Repair Tips

If you’re a DIY enthusiast, you can try some of these repair tips to fix the problem:

- Check the hydraulic fluid levels regularly and top up if necessary.

- Inspect the seals and hoses for leaks or damage. Replace them if necessary.

- Adjust the clutch cable tension, if needed.

- Replace worn or damaged clutch plates.

These DIY repair tips can help you fix the problem and get your Harley back on the road.

Here’s another problem you should be aware of: Your Harley Lost All Electrical Power? Here’s What To Do

Routine Maintenance and Inspection Practices to Avoid Issues

To keep your Harley’s hydraulic clutch in good working condition, regular maintenance and inspection are essential. Here are some tips to help you keep your clutch in top shape.

Checking Fluid Levels

One of the most important things you can do to maintain your hydraulic clutch is to regularly check the fluid levels. Low fluid levels can cause your clutch to slip or not engage properly. To check the fluid levels, locate the clutch fluid reservoir, which is usually located on the handlebars or near the engine. Check the fluid level against the minimum and maximum marks on the reservoir. If the level is below the minimum mark, add more fluid until it reaches the maximum mark.

Inspecting Clutch Components

Another important aspect of maintaining your hydraulic clutch is to regularly inspect the clutch components. Check the clutch plates for wear and damage. If the plates are worn or damaged, they should be replaced. Also, inspect the clutch springs for signs of wear or damage. If the springs are worn or damaged, they should be replaced as well.

Regular Maintenance Schedule

To ensure that your hydraulic clutch continues to function properly, it’s important to follow a regular maintenance schedule. Here are some tasks that should be performed regularly:

- Check the fluid levels at least once a month

- Inspect the clutch components at least once a year

- Replace the clutch fluid every two years

- Replace the clutch plates and springs as needed

By following these tips and performing regular maintenance and inspection, you can help ensure that your Harley’s hydraulic clutch continues to function properly. Proper maintenance can also help prevent costly repairs down the road.

content continues below

Quick Navigation for Related Problems

-

Harley Davidson Oil Leaks: Quick Fixes for a Sealed Ride

-

Harley Davidson Excessive Vibration: Tips to Smooth It Out

-

Harley Engine Knocking Sound: Causes and Fixes

-

4 Most Annoying Harley Davidson Throttle by Wire Problems

-

5 Harley Davidson Overheating Problems That Ruin Your Ride

-

3 Harley Davidson Brake Light Switch Problems To Be Aware Of

-

Total Harley Davidson Starter Problems Troubleshooting Guide

-

Harley Davidson Speedometer Not Working: Tips, Tricks & More

-

Harley Oil Breather Problems: Quick Tips, Tricks & More

-

Harley Oil Sumping Fix: Quick Solutions for a Smooth Ride

-

Harley Davidson ABS Light Flashing: Tips, Fixes, and More

-

Harley Davidson BCM Problems: Navigating Common Issues

-

Is Your Harley Clicking When Trying to Start? Help’s Here!

-

Harley Davidson Fuel Pump Problems: Tips, Tricks & More

-

3 Harley Davidson Fuel Injection Problems To Be Wary Of

-

Harley Bad Compensator Symptoms: Recognizing Early Signs

-

6 Reasons Why Your Harley Has Power but Won’t Start

-

Your Harley Lost All Electrical Power? Here’s What To Do

-

3 Harley Davidson Transmission Problems That Shift Your Mood

-

4 Harley Hydraulic Clutch Problems, Their Causes and Fixes

content resumes

Upgrades and Preventative Measures

If you own a Harley Davidson motorcycle with hydraulic clutch, you may experience issues with the clutch system over time. However, with proper upgrades and preventative measures, you can prolong the life of your clutch components and avoid costly repairs.

Upgrading Clutch Components

Upgrading your clutch components can help improve the performance and durability of your clutch system. For instance, you can install a stronger clutch spring to prevent clutch slipping problems that may arise after power upgrades.

You can also upgrade your clutch plates to improve the grip and reduce wear and tear. The Barnett Extra Plate Clutch Kit is a popular choice among Harley owners as it provides more surface area and friction than the stock clutch plates.

Another option is to upgrade your clutch cable to a stainless steel braided cable. This type of cable is more durable and resistant to breaking or kinking than the stock cable.

Preventative Practices

Preventative maintenance is key to prolonging the life of your clutch system. Here are some tips to keep your hydraulic clutch in good condition:

- Regularly check fluid levels and top up if necessary.

- Inspect seals and hoses for leaks or damage and replace them if necessary.

- Avoid riding your motorcycle with a slipping clutch as it can cause excessive wear and tear.

- Use a high-quality synthetic hydraulic fluid to ensure proper lubrication and prevent corrosion.

- Avoid overloading your motorcycle as it can put extra strain on the clutch system.

By following these preventative measures and upgrading your clutch components, you can ensure that your Harley Davidson motorcycle with hydraulic clutch runs smoothly and reliably for years to come.

Frequently Asked Questions

How can I troubleshoot issues with my Harley’s hydraulic clutch?

If you’re experiencing issues with your Harley’s hydraulic clutch, there are a few things you can try to troubleshoot the problem. First, check the fluid levels in the clutch master cylinder. If the fluid is low, top it off and see if that resolves the issue. If the fluid level is fine, you can try bleeding the clutch system to remove any air bubbles. If neither of these solutions work, it’s best to take your Harley to a professional mechanic for further diagnosis.

Has there been a recall on Harley-Davidson’s clutch actuator, and what models are affected?

Yes, there has been a recall on Harley-Davidson’s clutch actuator. The recall affects certain 2014-2015 Touring models, including the Electra Glide Ultra Classic, Electra Glide Ultra Limited, and Road King. The recall was issued due to a potential issue with the clutch master cylinder that could cause the clutch to not disengage properly.

Can regular maintenance prevent hydraulic clutch problems on my Harley?

Yes, regular maintenance can help prevent hydraulic clutch problems on your Harley. It’s important to check the fluid level in the clutch master cylinder regularly and top it off if necessary. You should also inspect the clutch system for leaks or damage and replace any worn or damaged parts. Regularly bleeding the clutch system can also help prevent air bubbles from forming and causing problems.

Leave a Reply

You must be logged in to post a comment.